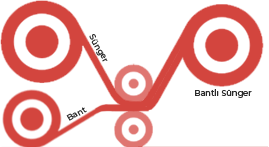

Lamination

Adhesive can be applying to one side or both side of the foam

Adhesive can be applying to one side or both side of the foam

Roll products can be splitting 4 mm to 1.500 mm witdh

Foams in block or roll form can be splitted between 1 mm to 50 mm.

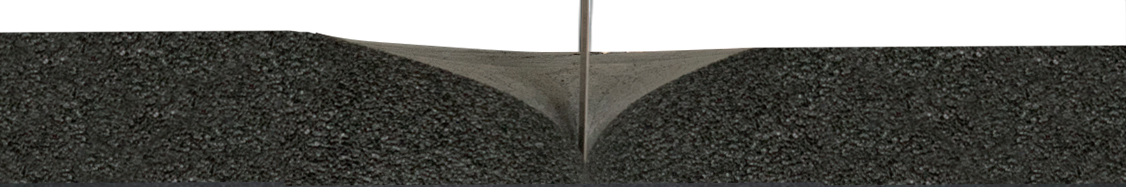

Foams in block form can be splitted vertically for requested form.

All the materials can be cutting according to technical drawings.

All the materials can be cutting according to technical drawings without cutting the liner.